Project-Management

| Name | Working area(s) | Contact | |

|---|---|---|---|

| Tobias Müller M.Sc. Electrothermal Characterisation of HVDC Insulation Systems | tobias.mueller5@tu-... +49 6151 16-20441 S3|21 403 |

Background

Due to the increasing demand for long national and international energy transmission lines, many high voltage direct current (HVDC) transmission projects with are being planned or are already in the construction phase (see figure). In Germany, the majority of lines are being implemented in the form of underground cables. The reliability of these power cable systems is fundamental to the success of energy transmission and grid stability.

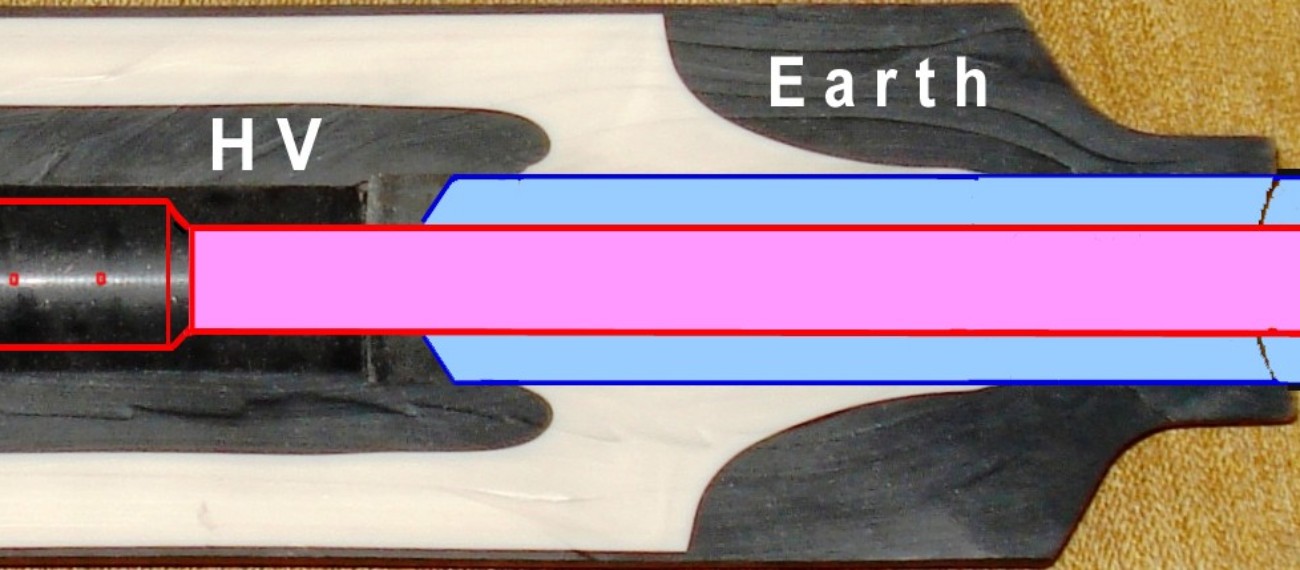

A large number of cable joints are required for land cable connections, as the cable sections are not produced longer than 1 to 2 km. This is mainly for transportation reasons on the roads. It is known from HVAC applications that cable accessories are susceptible to faults, especially cable joints. Due to additional risks it is suspected that cable joints also represent a weak point in HVDC systems. In addition to a good design, the development success of robust HVDC cable accessories depends heavily on reliable insulation materials.

Electrothermal Characterization

An important step in the design of high-voltage cable accessories is the determination of the electric field distribution within the multi-dielectric arrangement using numerical models (simulation). The models must take into account temperature and field-dependent electrical conductivity as well as space charge phenomena. The numerical models are based on data derived from electrical measurement series. In order to achieve robust calculation results, the experimental database must be reliable and take into account the relevant parameters of the operating conditions. The basis of this database is the experimental electrothermal characterization of the insulation materials, e.g. the direct current conductivity or the permittivity as a function of temperature.

The electric field distribution in the steady-state conditions depends on the conductivities of the insulation materials involved. The conductivities of different materials can be dependent on temperature and field strength. Furthermore, there is a temperature gradient during operation from the energized inner conductor to the outside of the cable. This results in an inversion of the electric field in relation to the de-energized cable.

In DC applications, there is also the possible accumulation of space charges in the insulation materials. Space charges influence the electric field distribution and charge transport in the insulation material. They therefore pose an additional risk to the reliability of the arrangement, both stationary (steady-state) and transient (field enhancement, polarity reversal, energizing and de-energizing, rapid earthing, transient overvoltages due to converter failures, breakdown or coupling of lightning impulse voltages).

Aim of this research project

The research program aims to gain a better understanding of the physical behaviour of HVDC cable joint materials. This is to be achieved by means of electrical and thermal characterization together with a high-precision calculation model. Thus, the “Pyrit” simulation software was developed and expanded in cooperation with the Department of Electromagnetic Field Theory (EMFT). It is based on the finite element method.

In addition to the characterization of individual materials, a complete HVDC cable joint is also to be characterized electrically and thermally, in particular to validate the simulations.

Finally, recommendations for the key dielectric properties of the materials should emerge from the investigations. By combining the experimentally recorded measurement data with the calculation model, new design concepts for HVDC cable joints can be developed.